CATEGORY COLLECTIONS

FEATURED CATEGORIES

Your One Stop Solution for LCD Displays

PRODUCT COLLECTIONS

FEATURED PRODUCTS

Visit Our Shop to See Full Range of LCD Displays

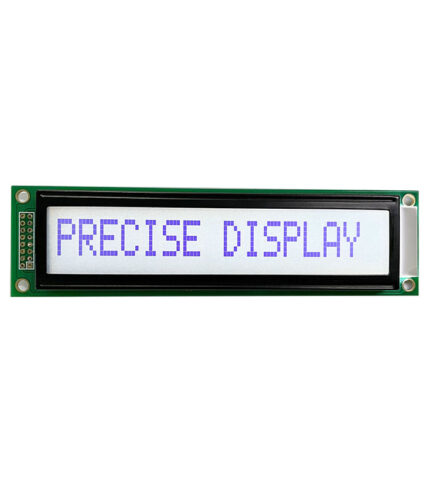

PCM1601G Sunlight Readable Character LCD Module with LED Backlight, Blue on White

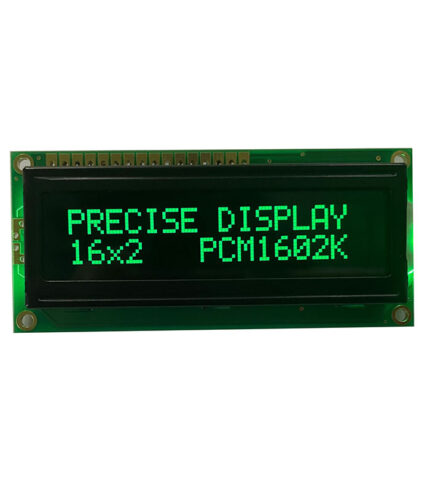

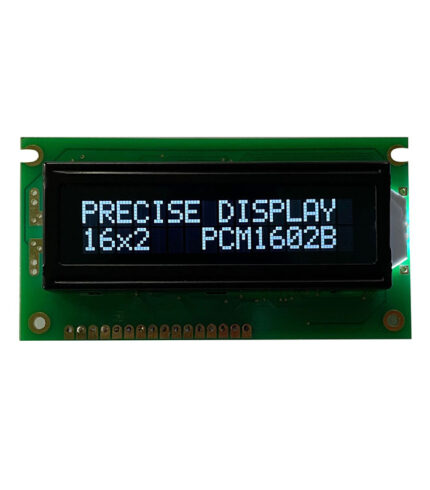

Login to see pricesPCM1602S Sunlight Readable Character LCD Module with LED Backlight, Black on White

Login to see pricesNEWS AND BLOG

Latest news and trends for industry

02

Jul

Belated: LG 40WT95UF is here with a 5K2K IPS black display and Thunderbolt 5 ports

-

Posted by

jeff

LG 40WT95UF was officially announced on June 4th, but LG’s official press statement did not mention any specific technical details except for the most important ones. We found data about this model on several certification-related pages and managed to create a listing with LG 40WT95UF specifications on our website, but the exact dimensions, weight, and power consumption have yet to be unveiled…

LG 40WT95UF was officially announced on June 4th, but LG’s official press statement did not mention any specific technical details except for the most important ones. We found data about this model on several certification-related pages and managed to create a listing with LG 40WT95UF specifications on our website, but the exact dimensions, weight, and power consumption have yet to be unveiled…

02

Jul

Philips 27M2N3500UK features the world’s first native hardware circular polarized display

-

Posted by

jeff

Philips Evnia and BOE jointly launched the world’s first native hardware circular polarized display. It is dubbed Philips Evnia Comfort Blue 4.0 or Circular Polarizing Light Panel and employs BOE’s new generation of circular polarization technology. Compared with traditional linear polarization technology, the trajectory of its light vector endpoint is circular, and the polarization direction is…

Philips Evnia and BOE jointly launched the world’s first native hardware circular polarized display. It is dubbed Philips Evnia Comfort Blue 4.0 or Circular Polarizing Light Panel and employs BOE’s new generation of circular polarization technology. Compared with traditional linear polarization technology, the trajectory of its light vector endpoint is circular, and the polarization direction is…

02

Jul

Philips 27M2N5800P from the Evnia 5000 series goes official with a dual-mode 4K IPS display

-

Posted by

jeff

Philips 27M2N5800P was quietly launched in Asia, so far in Singapore and Vietnam only. It is an interesting monitor that can appeal to those who want a single unit for both work and play. The model belongs to the Evnia 5000 series and arrives with the Evnia Precision Center software. It features a 27-inch Fast IPS display with a native 4K resolution and a 240Hz refresh rate with Adaptive-Sync…

Philips 27M2N5800P was quietly launched in Asia, so far in Singapore and Vietnam only. It is an interesting monitor that can appeal to those who want a single unit for both work and play. The model belongs to the Evnia 5000 series and arrives with the Evnia Precision Center software. It features a 27-inch Fast IPS display with a native 4K resolution and a 240Hz refresh rate with Adaptive-Sync…

02

Jul

Samsung shifts focus to consolidating existing ecosystem, cancels SFF

-

Posted by

jeff

Samsung Electronics will no longer hold its customary Samsung Foundry Forum (SFF) in 2025, opting instead to host partner-exclusive events, drawing attention from industry observers. This move is interpreted as part of Samsung Semiconductor’s strategy to emphasize “strengthening internal capabilities.”

02

Jul

Taiwan-India JV powers breakthrough as MiPhi launches India’s first enterprise-grade SSDs

-

Posted by

jeff

According to the Business Standard, BW Business World, and EE Herald, MiPhi Semiconductors, a joint venture between India’s Micromax Informatics and Taiwan’s Phison Technology, has announced the design and manufacture of enterprise-grade SSDs in India, making MiPhi the first indigenous brand to produce such high-performance data storage solutions in the country.

02

Jul

AI programming fuels venture capital surge amid tech giants’ rivalry

-

Posted by

jeff

The AI programming sector is experiencing a surge in venture capital investment as startups like Anysphere and Windsurf command multibillion-dollar valuations despite being unprofitable. Simultaneously, technology giants Microsoft and Alphabet Inc. are intensifying competition by launching their own AI coding tools and services.